- HOME

- Screen Printing Mesh Business

- Screen Printing Process

Screen Printing Mesh BusinessScreen Printing Process

Screen Printing Process

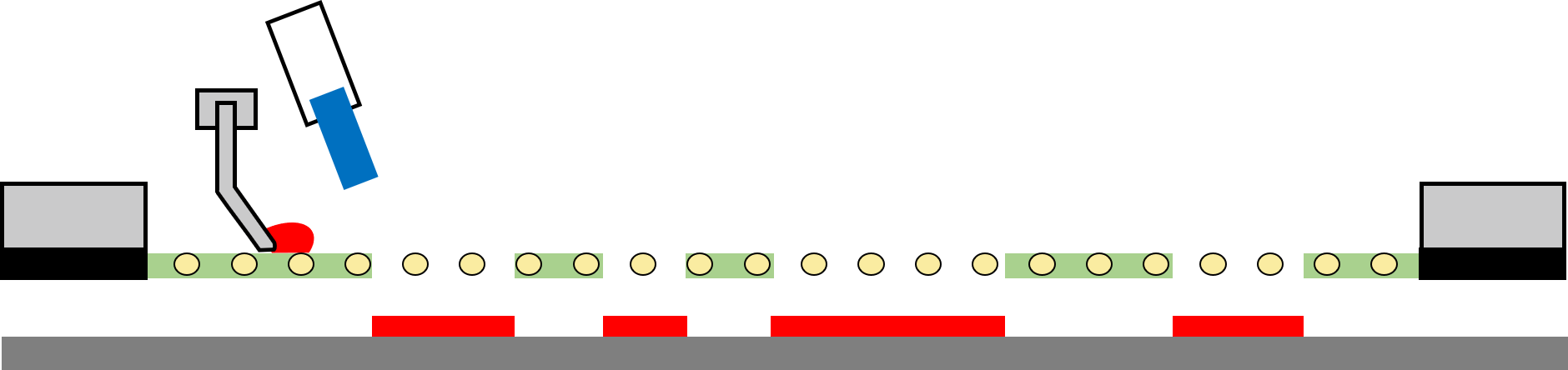

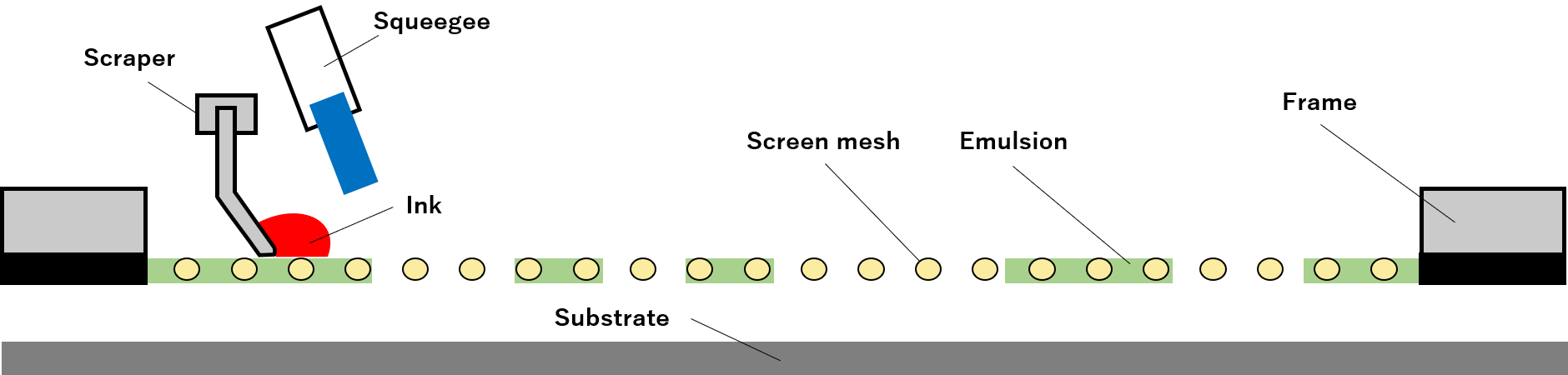

Screen printing is a form of stencil printing where a textile (screen) woven with a synthetic fiber (such as polyester and nylon) or a metal thread (such as stainless steel and tungsten) is used as a printing screen, and ink that is put through spaces between threads with a paddle like material called squeegee is directly printed onto a material.

Screen Making Process

- Prepare a Frame and

Positive Film -

(Positive film)

(Positive film)Prepare a frame that is suitable for the size of printed matter. Frames are made of aluminum, casting, or wood.

- Mesh Stretching

-

Stretch the while applying tension uniformly in the longitudinal and lateral directions with a stretching machine. After reaching a preset tension, join the mesh and frame with adhesive.

- Emulsion Application

-

Apply an UV curing emulsion after degreasing and drying the stretched screen.

- Positive Film Placement

-

Attach positive film to the printing side after emulsion is dried sufficiently.

- Exposure + Development

-

The emulsion that was not illuminated with ultraviolet light during exposure and did not cure is flushed with water, and the mesh parts are exposed. The printing plate is completed after it is dried and inspected.

Printing Process

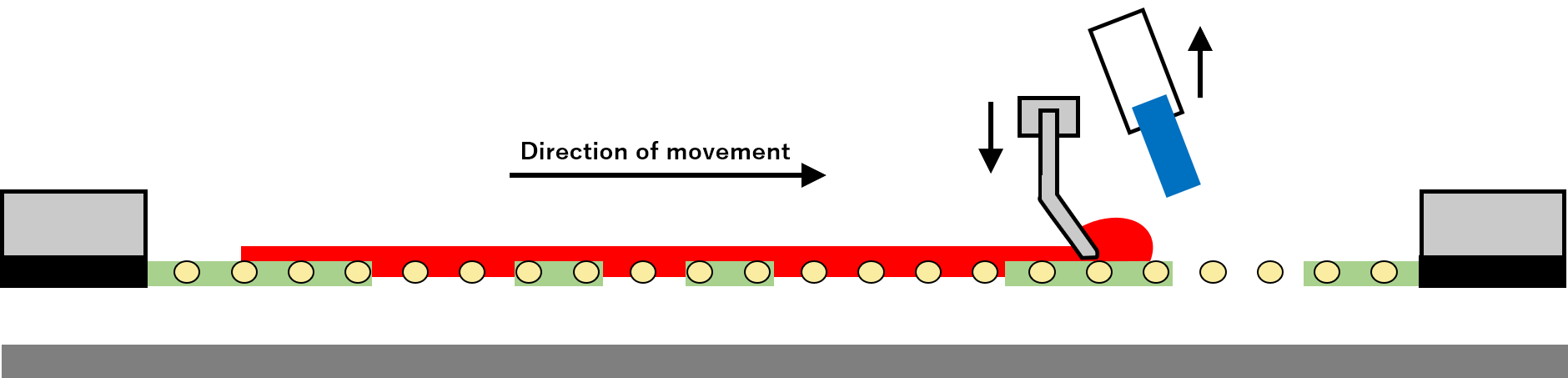

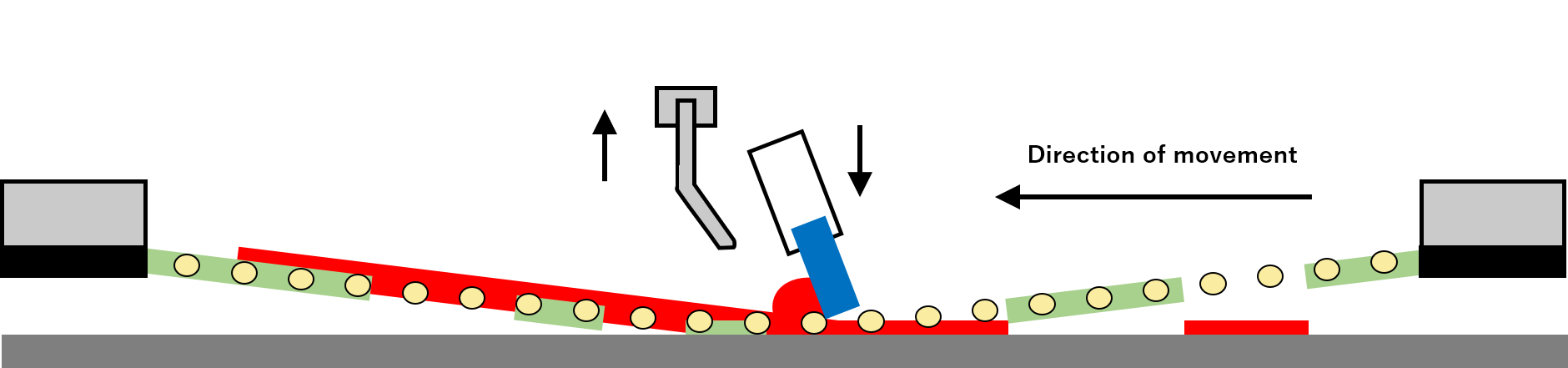

- 1.Preparation

- Place the prepared screen, ink, and the substrate on a printing machine.

- 2.Filling of Ink

- Fill ink using a scraper.

- 3.Begin Printing

- The squeegee is pressurized to push the ink out.

- 4.Print Completed

- The ink is transferred to the substrate.