- HOME

- Industrial Material Textile Fabrics Business

- Filters

- Processing Technologies

Industrial Material Textile Fabrics BusinessProcessing Technologies

Processing Technologies

Ribbon Processing

Rolled original fabric is reeled while it is cut (slitted) continuously in a fixed width.

In addition to textile fabric mesh, films, welding tapes, nonwoven fabrics produced in extended lengths or larger widths are processed into certain sizes according to the application.

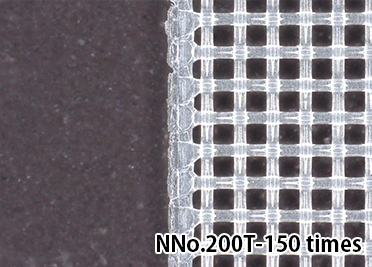

Ultrasonic Slitting

Mesh materials are slit while crushing the edge with ultrasonic vibration.

| Processing width | Tolerance | |

|---|---|---|

| Minimum width | 2.8mm | ±0.1~0.3mm |

| Maximum width | 30mm |

The tolerance range varies depending on the material and product number. Please contact us for details.

Ultrasonic Slitted Surface

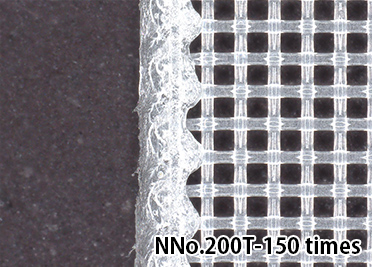

Heat Slitting

The mesh is slitted by heat treatment (temperature close to melting point). This process is also called melt-slitting or melt-cutting.

| Processing width | Tolerance | |

|---|---|---|

| Minimum width | 12mm | ±0.3~3.0mm |

| Maximum width | 1,600mm |

The tolerance range varies depending on the material and product number. Please contact us for details.

Heat Slitted Surface

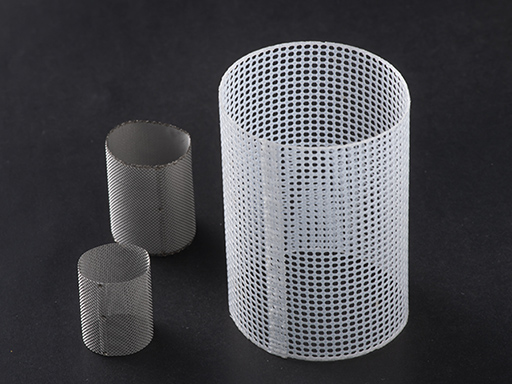

Tube Processing

Meshes are welded into tubes by the methods called ultrasonic welding and thermal welding.

Automated Machine (Ultrasonic)

| Inner diameter | Tolerance | Height | Tolerance | |

|---|---|---|---|---|

| Minimum size | φ3.0 | ±0.1~0.3mm | 4mm | ±0.1~0.5mm |

| Maximum size | φ56 | 45mm |

The tolerance range varies depending on the material and product number. Please contact us for details.

Automated Machine (Heat)

| Inner diameter | Tolerance | Height | Tolerance | |

|---|---|---|---|---|

| Minimum size | φ14 | ±0.3mm | 20mm | ±0.3~0.5mm |

| Maximum size | φ50 | 56mm |

The tolerance range varies depending on the material and product number. Please contact us for details.

Manual Processing (Heat)

We can handle products of shapes and sizes that cannot be manufactured by automatic machines.

| Inner diameter | Tolerance | Height | Tolerance | |

|---|---|---|---|---|

| Minimum size | negotiable | negotiable | ||

| Maximum size | φ120 | ±0.5mm | 180mm | ±0.5mm |

The tolerance range varies depending on the material and product number. Please contact us for details.

Tube Welding Types

-

Lap Welding (Jointed Surface)

High welding strength. The productivity is low and small-sized parts cannot be welded.

-

Corner or Edge Welding (Jointed Edge)

Welding strength is low, but productivity is high and even small-sized parts can be welded.

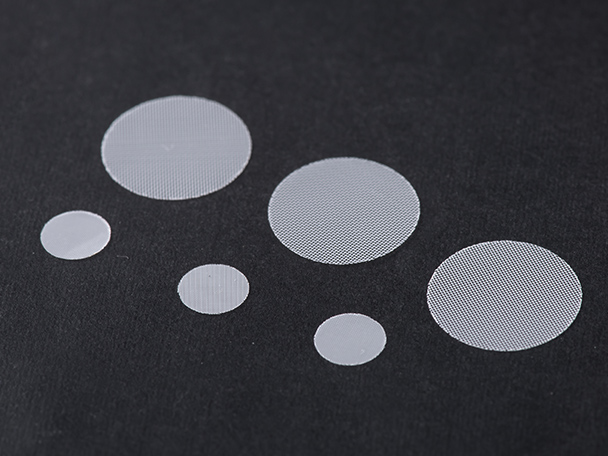

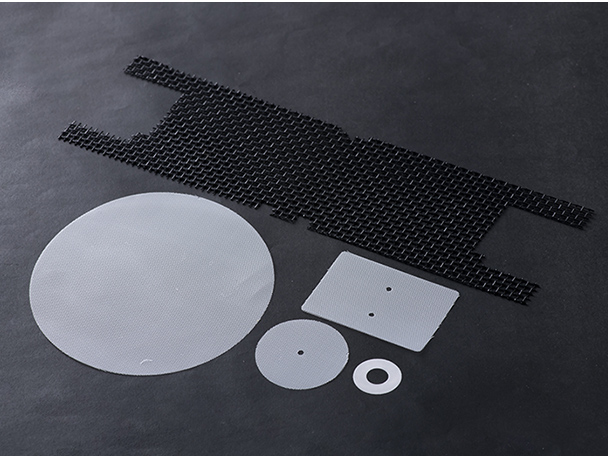

Punching Process

Mesh is punched out into desired shapes by placing the material between the punch and die.

Ultrasonic Waves

Cutting with ultrasonic waves prevents product edges from fraying.

| Size | Tolerance | |

|---|---|---|

| Minimum size | φ5 | ~±0.5mm |

| Maximum size | φ20 |

The tolerance range varies depending on the material and product number. Please contact us for details.

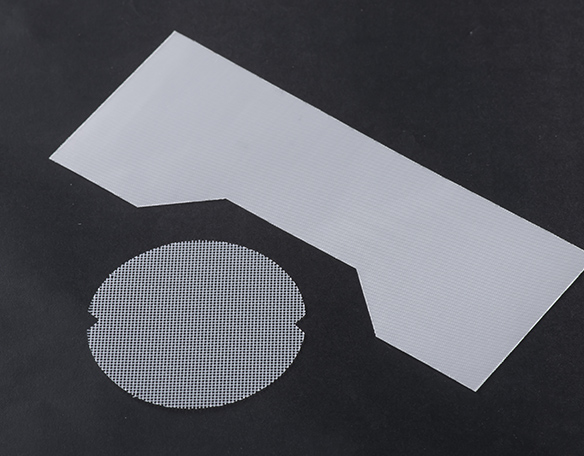

Die cutting

A process where various materials can be punched out with a press using a Thomson die (wooden die).

Fraying of product edges cannot be prevented as in cutting with ultrasonic waves.

| Size | Tolerance | |

|---|---|---|

| Minimum width | φ4 | ±0.3~1.0mm |

| Maximum width | φ600 |

The tolerance range varies depending on the material and product number. Please contact us for details.

Laser Cutting Process

Products of all shapes and sizes can be processed with laser beam and the fraying of the product edges can be prevented.

| Effective processing area | Minimum processing size | Tolerance |

|---|---|---|

| 1,300mm×900mm | 10mm×10mm | ~±0.5mm |

The tolerance range varies depending on the material and product number. Please contact us for details.

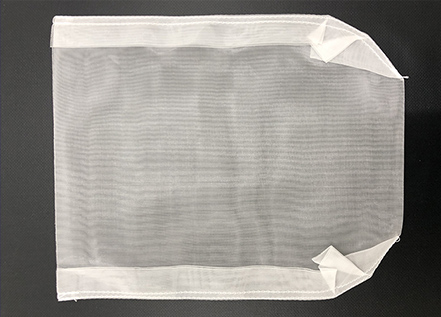

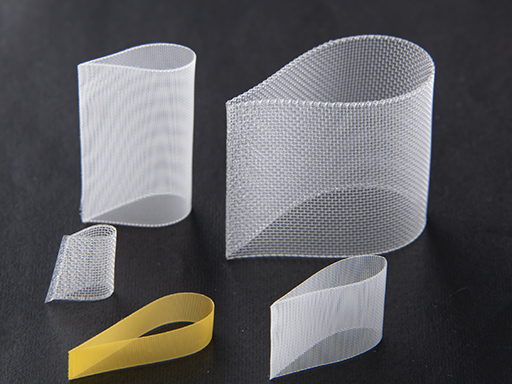

Sewing

Various shapes and sizes can be sewn to meet customer demands.

The thickness and color of the threads, as well as the use of a patch, can be customized in different ways.