- HOME

- Weaving Technologies

Our TechnologiesWeaving Technologies

Creating and Controlling “Space” - Nittoku's Weaving Technologies

Paved the way to becoming an industrial textile fabric manufacturerby enhancing traditional technologies

Nittoku, founded in 1954 as a habutae silk manufacturer, has enhanced its weaving technologies to higher levels over time and advanced from the apparel field into the non-apparel field. Today, it is evolving every day as an industrial textile fabric manufacturer that develops and creates a wide variety of mesh products using synthetic and metal/carbon fiber.

Controlling “Space” with micron accuracy

creating a variety of products with Nittoku's precision technology

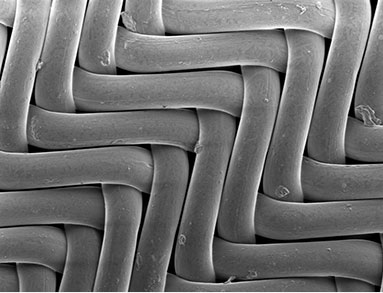

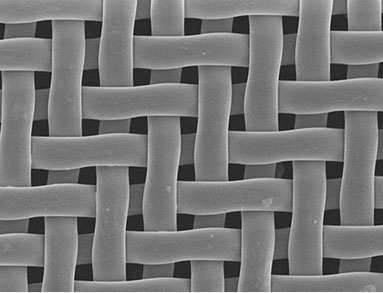

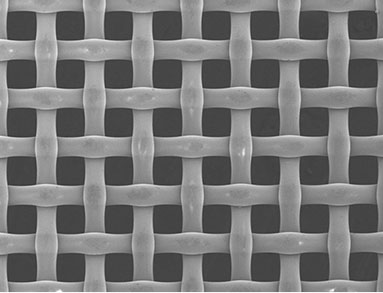

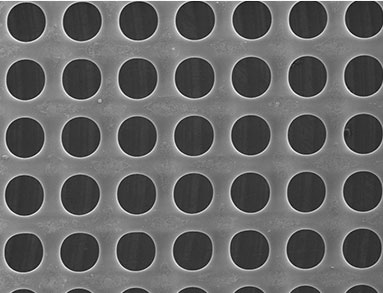

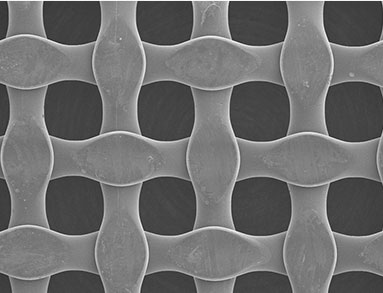

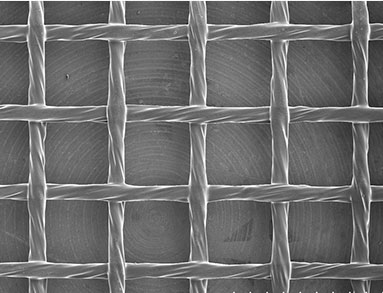

Nittoku's core technology enables the weaving of "Space," which are the openings created by warp and weft threads, as desired with micron accuracy from microns to centimeters in length and width.

Our family of products created from this technology is widely used in different forms in a diverse range of fields, such as screen printing, precision manufacturing, and medical care.

Nittoku's Weaving Capabilites

Weavable Material

We can weave polyester, nylong, polyethylene, polypropylene, along with any kind of materials that can be made into threads.

- Polyester

- Nylon

- Polyethylene

- Polypropylene

- Fluorine

- Copper

- Carbon

- PPS

- Stainless steel

- Superfiber

Maximum Weavable Sizes

- Screen Printing Mesh

- Up to approximately 3,050 mm

- Industrial Material Textile Fabrics

- Up to approximately 4,200 mm

Weavable Mesh Opening Sizes

Mesh is formed by warp and weft yarns that cross each other at right angles, and we can create small square spaces in a variety of sizes with micron accuracy.

- Mesh

- We have achieved a wide range of meshes from 30 to 2,000 µm openings.

We propose fine meshes based on customer needs.

We can weave any kind of textile fabric to meet customer needs in a flexible manner.

Please feel free to contact us anytime!