- HOME

- Industrial Material Textile Fabrics Business

- Filters

- Mesh Specification Values

Industrial Material Textile Fabrics BusinessMesh Specification Values

Mesh Specification Values

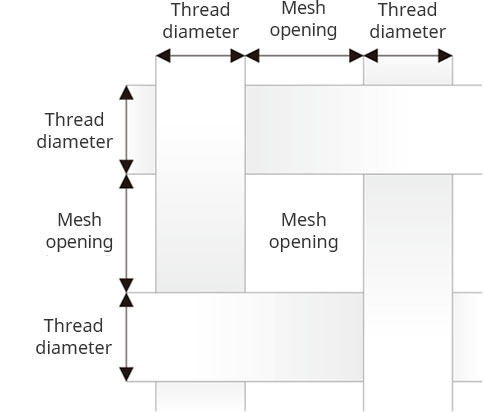

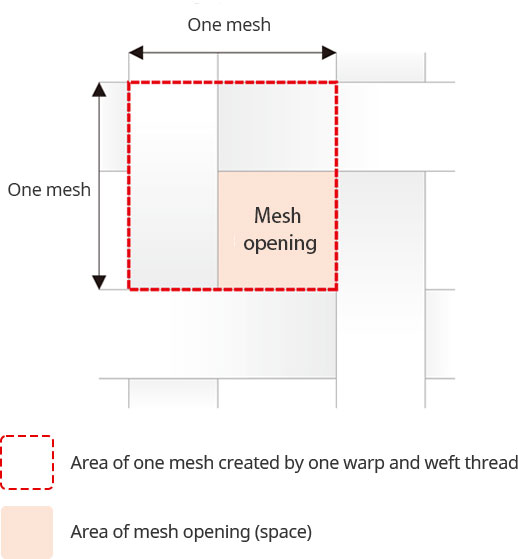

| Mesh count | Number of threads per inch |

|---|---|

| Thread diameter | Diameter of a thread(㎛) |

| Mesh opening |

Distance between threads(㎛)

|

| Open area |

Open area percentage (%)

|

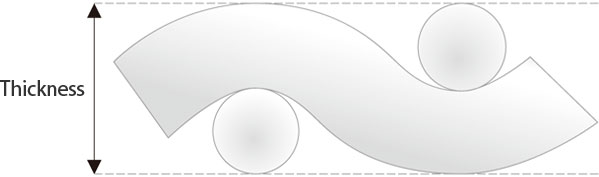

| Mesh thickness | Thickness of mesh(㎛) |

| Volume |

Theoretical volume(㎤/㎡)

|

- ※The specifications are values in a tensionless state.

- ※The thread diameter is a value before weaving.

Basic Knowledge About Mesh

Thread types

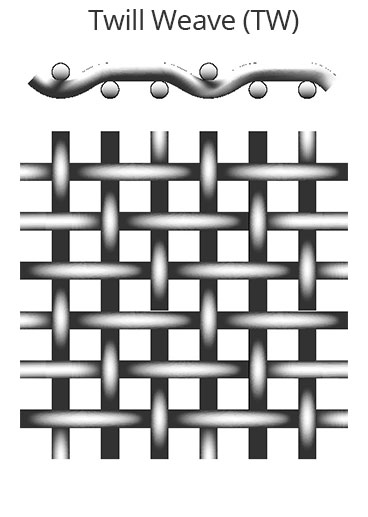

Twill weave is a structure created by intersecting warp and weft yarns. Each yarn is woven by at least skipping two or more of the opposing yarn either over or under. Slanting ribs like "/" can be seen as a diagonal pattern on the fabric surface. This slanting line is called the "twill line."

Twill weave yard has a slightly lower durability, but is more flexible and has a glossy texture compared to plain weave as the warp of a twill weave yarn will cover a larger surface area. (warp yarns are floated in a wider area).

As there are fewer interlacing threads, high-density textile fabrics with fewer spaces can be created.

A weave in which the weft yarns are crossed by two upper and two lower warp yarns is called "2/2 twill weave", and weaves in which weft yarns are crossed by two upper and one lower and three upper and one lower warp yarns are called "2/1 twill weave" and "3/1 twill weave," respectively. A wide variety of structures that cannot be realized with a plain weave can be created.

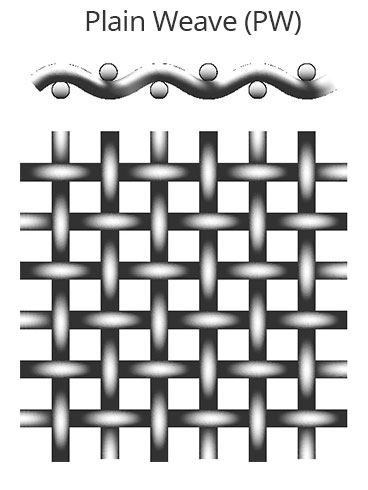

Plain Weave (PW)

Plain weave is made by crossing the warp and weft yarns with each other, which is the simplest weave among textile structures. Well regulated and highly durable textile fabrics can be created as there are many points where the threads cross each other (structure points). It is also resistant to friction.

Since the warp and weft yarns appear on the front and rear surfaces of the textile uniformly, it is sometimes difficult to make a distinction between the front side and the rear side compared to other structures.

![Calculation formula for [Mesh opening]](/en/products/screen/image/spec_calc_photo01.jpg)

![Calculation formula for [Open area]](/en/products/screen/image/spec_calc_photo02.jpg)

![Calculation formula for [Volume]](./image/spec_calc_photo03.jpg)